LASER CUTOUTS is a family owned and run business that has been successfully trading for approximately nine years in Washington, Tyne & Wear.

What was primarily set up for laser cutting and engraving has now also evolved into wood crafting and box production. After being approached by a charity to see if the company could produce memory boxes, the team first began with laser cut out boxes. These required a great deal of manpower to complete as they still needed to be glued, clamped and left to dry. From this the company moved to a locking mitre joint, which was better but still required gluing, clamping and time to dry.

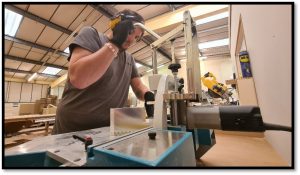

Whilst visiting the 2019 annual Northern Woodworking Show in Harrogate, company director Paul Stott came to the Hoffmann Machine Company stand. He was given a demonstration of the Hoffmann MU3 dovetail routing machine by Sean, one of the Hoffmann team. He produced a simple but strong mitre joint in a matter of seconds. Paul was impressed, and sent Sean some samples of his 9 mm thick poplar wood to test the accuracy and strength of the joints. A range of samples was produced using different sized Hoffmann dovetail keys (W2-W0). It was agreed that the joint using the Hoffmann W0 key would offer the ideal solution. Paul was so impressed with the samples that the Hoffmann MU3 dovetail routing machine was purchased immediately, and the company hasn’t looked back since!

Paul Stott commented: “With very limited training all our staff can now produce all parts of the box, eliminating the need to employ a dedicated member of staff. We can now produce the joints and start assembly immediately with no clamping required. The finished joints are tighter and stronger and add to the quality and finish of the box. Not only has the Hoffmann dovetail jointing system improved the quality of the joints, the production time has been reduced by two-thirds, increasing productivity!”

Laser Cutouts are currently producing four different sized boxes from small (150 mm square) up to large (400 mm square). The new Hoffmann W0 key is one third smaller than the already legendary W1, so it was ideal to use on Paul’s 9 mm thick profiles. With a cross sectional size of just 3.3 mm x 4.4 mm, it will draw together profiles as thin as 7 mm and upwards with startling strength.

Hoffmann offers joint processing of customer’s profiles for assessment and approval.